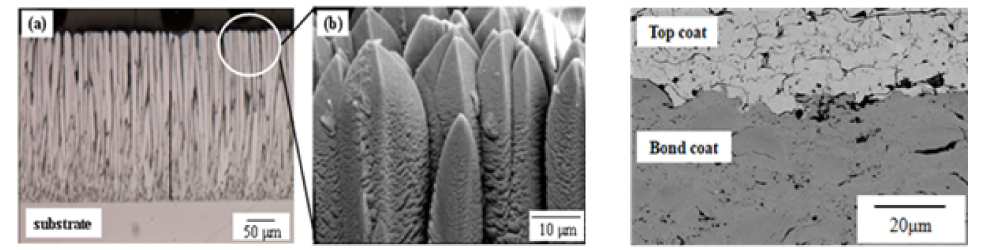

Thermal barrier coatings are of enormous technological importance because they increase the thermal efficiency of gas turbine engines by allowing higher inlet temperatures and reducing the amount of cooling air required for the hot-section components. To optimize TBCs for integration into gas turbines, the relationship between microstructure and thermal/chemical/mechanical properties of the coatings needs to be characterized. Our research focuses on evaluating chemical corrosion caused by volcanic ash, as well as thermal properties and microstructures of ZrO2—4 mol% Y2O3 (YSZ) coatings deposited by air plasma spray (APS) or electron beam physical vapor deposition (EB-PVD).

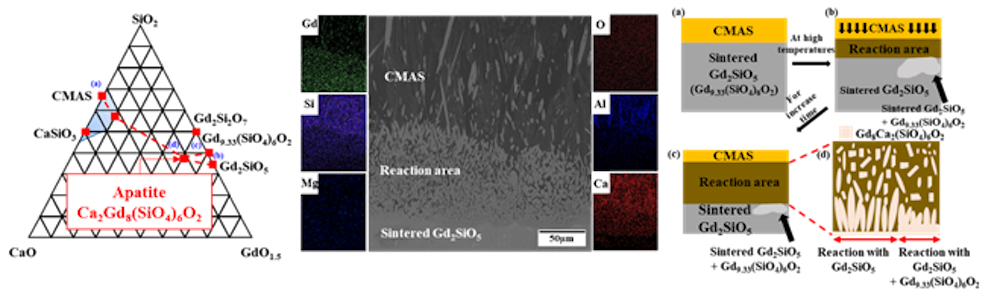

Disadvantages of using silicon carbide (SiC) and SiC/SiC composites as substrates for components in gas turbines exposed to combustion gases include their vulnerability to corrosion and volatilization of silica (SiO2). EBCs help solve this problem by shielding the SiC and SiC/SiC composites from the harsh environment. In particular, rare earth silicates with high heat and oxidation resistance appear to be ideal candidate materials for EBCs. The purpose of this study is to evaluate the high-temperature corrosion of rare earth silicates exposed to volcanic ash or synthetic calcium-magnesium-aluminosilicate (CMAS: CaO-MgO-Al2O3-SiO2) and characterize the mechanical properties of these EBCs using nanoindentation.

CaO-SiO2-GdO1.5

Gd2SiO5 with CMAS

Gd2SiO5 with CMAS

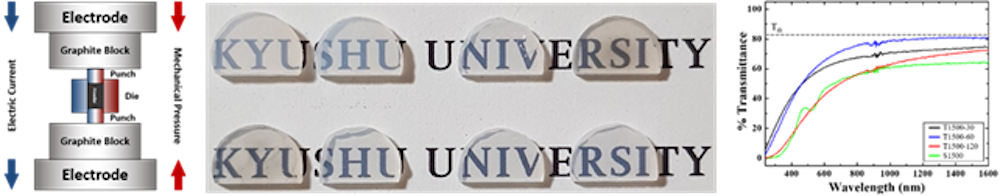

Transparent ceramics such as Y2O3 and Ln3Al5O12 (lanthanide aluminate garnet, LnAG) are promising candidates for lasers and scintillators. To facilitate laser oscillation, a transparent ceramic must have a light transmittance equivalent to its single crystal form; unfortunately, even if only 0.1% of pores remain in the ceramics after sintering, the transmittance decreases, and laser oscillation is difficult to achieve. SPS can be used to fabricate functional transparent ceramics with significantly enhanced sinterability and minimal porosity by simultaneously applying an electric field and pressure. The objective of this research is to develop improved methods for fabricating highly transparent functional ceramics for use in lasers and scintillators.

SPS equipment

transparent Y2O3

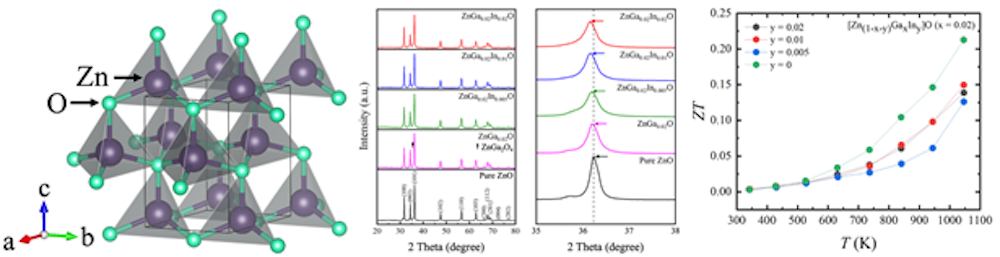

Depletion of fossil fuels and rapid global warming make it imperative to develop alternative energy sources. Thermoelectric (TE) energy conversion is a potential technology for power generation from renewable or unused energy sources. The conversion efficiency of a TE material is generally expressed as a dimensionless figure of merit, ZT = S2σTκ−1, where S, σ, T, and κ are the Seebeck coefficient, electrical conductivity, and thermal conductivity, respectively, of the material, and T is absolute temperature. ZnO is one of the most important TE materials known to date for energy conversion at high temperatures, with ZT = 0.6 at 1247 K. One of the main factors limiting use of ZnO as a TE material is its high thermal conductivity. A strategy we are using in our research to overcome this problem is doping with elements such as In and Ga.

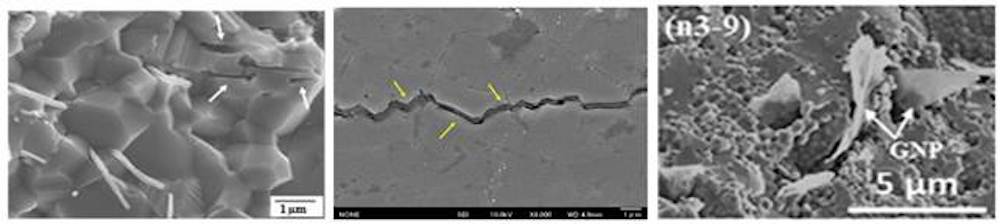

Carbon nanotubes and graphene are fascinating materials because of their unique structural, electronic, physical, and thermal properties. The goal of this research is to develop CNT- or graphene-reinforced nanocomposites with superior mechanical properties, particularly hardness and toughness, which influence wear characteristics. In addition, sintering and mechanical properties of Al2O3/CNTs, HAp/CNTs and graphene nanoplatelet (GNP)-reinforced hydroxyapatite (HAp) composites are also being investigated. We are also studying the effect of CNT-reinforcement on the transformation toughening mechanism and the fracture toughness of 3 mol% yttria-stabilized zirconia (YSZ).

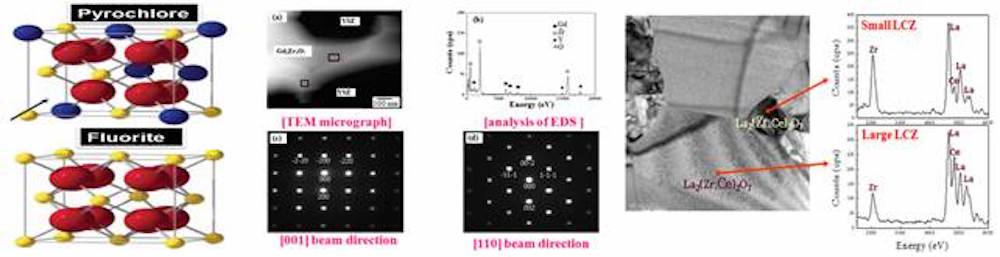

Reacting lanthanide oxides (e.g., La2O3, Gd2O3) with zirconia (ZrO2) produces zirconates (e.g., La2Zr2O7, Gd2Zr2O7) with a pyrochlore or fluorite crystal structure. These zirconates have low thermal conductivities and good stability at temperatures above 1200°C. This research is aimed at understanding the effect of La2O3 and Gd2O3 addition on the thermal conductivity of ZrO2—4 mol% Y2O3 ceramics fabricated by spark plasma sintering. Thermal properties of materials in the La2(ZrxCe1−x)2O7 system with a mixed fluorite-pyrochlore structure are also being studied. Research into the effect of Y2O3 addition on thermo-electrical properties of SiC is also being carried out to aid development of electrical discharge-machinable ceramics.